Multidisciplinary Research Centre

College for Women, University of Delhi

Centres and Special Labs

About

Miranda House has taken a significant step in establishing a Multidisciplinary Research Centre (MRC) that serves as a dynamic and thriving environment for fostering progress in research, innovation, product development, and the practical application of science and technology. The MRC not only promotes growth and advancements but also provides a valuable platform for technology transfer and patents, facilitating the transfer of knowledge and discoveries to practical applications.

One of the prominent entities operating under the MRC is the Smart Materials and Devices Laboratory (SMLD). This laboratory is fully committed to pioneering research in areas of paramount importance, specifically addressing the nation's pressing requirements in device manufacturing and translational efforts. It aims to bridge the gap between research and practical application by actively engaging in cutting-edge research and development endeavors.

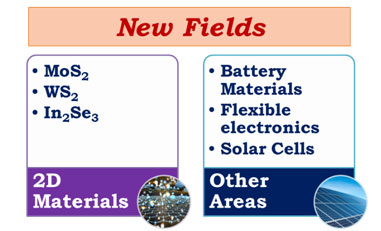

The SMLD houses several specialized laboratories that contribute to various fields of material science. These laboratories cover a wide range of research areas, including but not limited to device fabrication, optoelectronic devices, energy harvesting and storage devices, and different types of sensors, such as physical, chemical, and biological sensors. Additionally, the laboratory is also involved in research on memory devices, exploring novel technologies and techniques for efficient data storage and retrieval.

Within the SMLD, researchers are dedicated to pushing the boundaries of knowledge in these fields, striving to develop innovative solutions that address critical challenges and fulfill the national needs. By conducting advanced research and fostering collaboration among scientists, engineers, and experts, the SMLD aims to contribute significantly to the development of state-of-the-art technologies and materials that can revolutionize various industries and improve the overall quality of life.

Achievements

Faculty members from Physics, Chemistry and Zoology Departments have been given formal recognition by the DU Board of Research Studies for independent supervision of Ph.D. students. The first independently guided Ph.D. thesis was submitted in 2015. At present more than 10 research scholars are working towards their Ph.D. thesis work in MRC.

Research groups at MRC have published more than 350 research papers in journals of high repute. Physics Department has published 01 USA Patent (Granted), 06 Indian Patent (published) and 04 Indian Patent (applied).

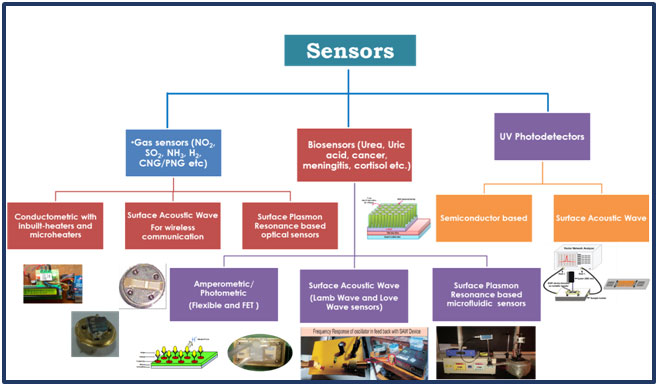

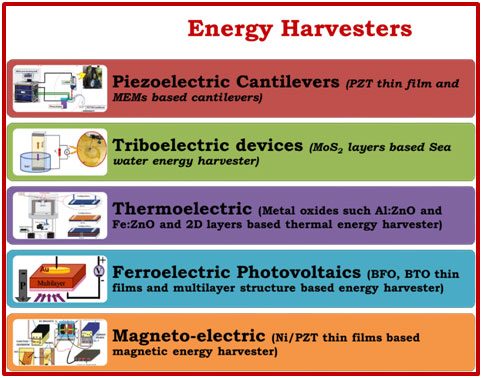

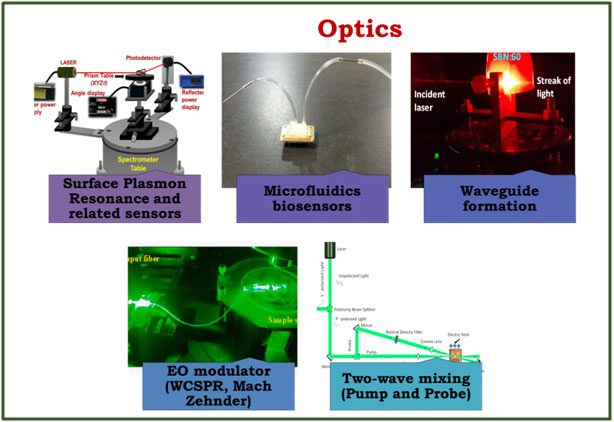

Research groups at SMDL are working on the development of functional materials for various electronic devices including acoustic sensors, biosensors, gas sensors, and UV-photo detectors. They are also fabricating multiferroics and piezoelectric materials for energy harvesting besides development of surface acoustic wave devices and MEMS based micro-heaters. The group working at SMDL have successfully developed table top Surface Plasmon Resonance set up to study the optical properties of various materials and detection of bio-molecules, chemical species, and gases besides the realization of temperature and magnetic field sensors. The technology of the SPR set up has also been transferred to industry.

Objectives

- A Multidisciplinary Research Centre builds on the aims and achievements developed by a Strategic Research Initiative over time.

- Establishment of the state-of-the-art experiments which could meet the objectives of the current New Education Policy (NEP, 2020) set by Government of India. Resulting in catalysing the quality academic research in all fields of basic sciences by introducing the regulatory mechanism and to create a conducive environment in the institution which support research in the higher education

- Encouragement towards the collaborative research work between faculty and students so that both ways learning and exploring process could be originated.

- Meeting the objectives of NEP reformed curriculum where students will be encouraged to acquire leadership roles which are honed by exposure to and interaction with leading experts in the field of science and technology, academicians, practitioners, and a plethora of government, non-government and international bodies. This will help Miranda House to provide a bridge to students, to cross over to the professional world.

- Inclusion of International collaboration and funding for the diversification of higher education at global level.

- Looking forward towards the growth and expansion of interdisciplinary research without compromising on the quality.

- Engagement with the external world to create more employment and internship opportunities.

Collaborations

One of the objectives of MRC is to collaborate with the industry which will act as an ecosystem that shall promote growth through scientific research, innovation, product development and application of technology, while also providing a mechanism for technology transfer and patents. MRC aims to expand its existing collaboration with R&D organizations such as DRDO, ISRO, STARC, SCL, GAIL etc.

MRC primarily focuses on nano-technology, fabrication of sensors, transducers, MEMS (Micro Electro-Mechanical systems) devices, AI driven start-ups, green energy technologies, energy harvesting solutions etc. which need support for commercialization and further proliferation. These can act as a growth driver in the low-end spectrum of the incubation eco-system.

It also aims to develop its own entrepreneurship cum skill development cell where hands on experience through short term certification programs will be given to students of undergraduation and postgraduation.

Research @ MRC

Facilities Available at SMDL

| Processing equipment | Electrical characterization | Other characterization |

| Mask-less Lithography | Keithley High Precession DMM | Ultra violet detector spectral response |

| RF & DC sputtering with Balanced & unbalanced magnetron (Qty: 03) | Keysight Picometer | Visible light detector spectral response |

| Hot Filament CVD System | Electrometers (Keithley and Keysight) | Triboelectric measurement set up |

| Vacuum Thermal evaporation | Source Measuring Unit (Dual Channel): Keysight | Surface plasmon resonance setup |

| Thermal Oxidation Furnace | Electrochemical Analyser (Palmsense) | Deep Freezer for biomolecules |

| Sol-gel processing facility Target and ceramic processing facility | Impedance Analyzer (C-V characteristics (20MHz)) | Thermoelectric Set up |

| Electrophoretic film growth setup | High resolution Digital Storage Oscilloscope | Chemical & Gas sensor test rig |

| Temp. controlled Furnaces 1400 oC | Lock-in-amplifier | Electro-optic set up |

| Controlled Si etching setup for system | HP Pulse generator | Pump and Probe set up |

| Ultrasonic & plasma glow cleaning | Sun Simulator | Optical Power meter (pW-mW) |

| Optical microscope (1000 X) | Low frequency LCR meter (10mHz-100KHz) | UV, VIS, and IR filters |

| Dedicated furnace for nanostructure growth | Keithley source-measure unit | Processor control XYZØ rotation |

| Spin Coater Units (Qty: 04) | Nanovoltmeter Keithley | Perkin-Elmer UV-Visible spectrophotometer |

| Spray Pyrolysis set up | Hall measurement set up | Optical Benches and Matrix board |

| Air compressor | Electrochemical Analyser for CV, EIS, DPV and chrono amperometric studies | Wafer dicer and wire bonder for device packaging |